Semiconductor Equipment

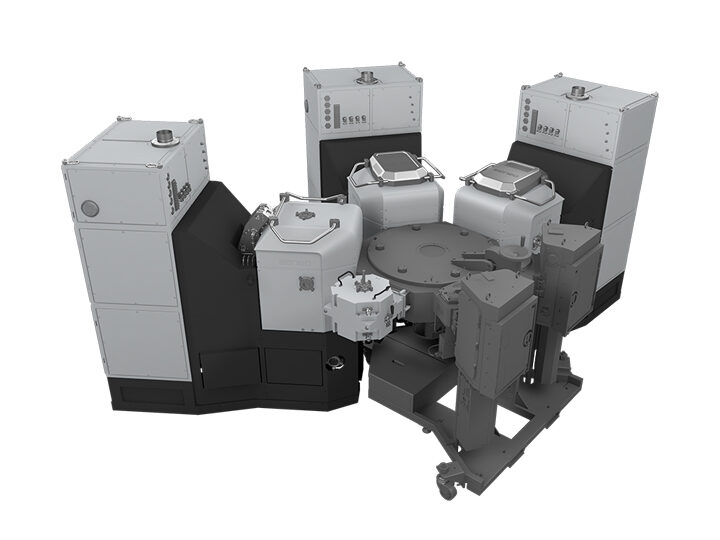

Beneq Transform®

Versatile, automated ALD solution for high-throughput production.

Equipment

Transform Tech Specs

Transform®

Transform® Lite

Maximum configuration

3 ALD modules & 1 pre-heater

2 ALD modules & 1 pre-heater

Preheating capability

Yes

Yes

Transfer module

Brooks Mx600SS

Brooks Mx400

Cooling option

Built-in

Facet-mounted

VCE loadlocks

2

1

Substrate Size

75, 100, 150, or 200 mm

75, 100, 150, or 200 mm

Substrate

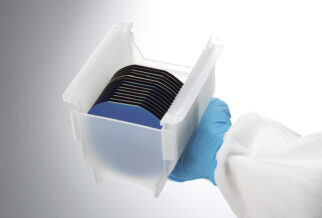

Si, GaN-on-Si, GaAs, InP, SiC, GaN, LNO, Sapphire

Si, GaN-on-Si, GaAs, InP, SiC, GaN, LNO, Sapphire

Maximum configuration dimensions

3000 x 3000 x 2250 mm

3000 x 1250 x 2250 mm

Integration

SECS/ GEM

SECS/ GEM

Transform®

Maximum configuration

3 ALD modules & 1 pre-heater

Preheating capability

Yes

Transfer module

Brooks Mx600SS

Cooling option

Built-in

VCE loadlocks

2

Substrate Size

75, 100, 150, or 200 mm

Substrate

Si, GaN-on-Si, GaAs, InP, SiC, GaN, LNO, Sapphire

Maximum configuration dimensions

3000 x 3000 x 2250 mm

Integration

SECS/ GEM

Transform® Lite

Maximum configuration

2 ALD modules & 1 pre-heater

Preheating capability

Yes

Transfer module

Brooks Mx400

Cooling option

Facet-mounted

VCE loadlocks

1

Substrate Size

75, 100, 150, or 200 mm

Substrate

Si, GaN-on-Si, GaAs, InP, SiC, GaN, LNO, Sapphire

Maximum configuration dimensions

3000 x 1250 x 2250 mm

Integration

SECS/ GEM

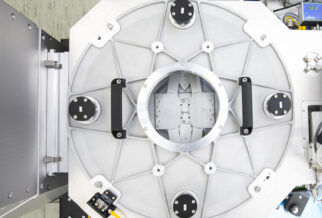

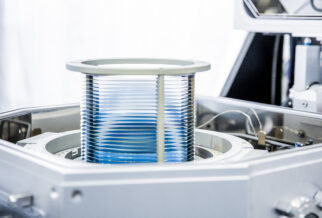

ALD Batch Process Module

Batch size

1, 10 or 25 wafers, up to 200 mm

Safety standards

SEMI S2 and S8

ALD processes

Al2O3, HfO2, Ta2O5, TiO2, SiO2, AlN, TiN (Others and metals to be released)

Processing temperature

Up to 420 °C

Liquid source lines

4

Ammonia (NH3) gas line

Optional

Ozone gas line

Optional

Process control

Recipe-based; fully configurable

ALD Plasma Process Module

Single wafer

Up to 200 mm

Safety standards

SEMI S2 and S8

ALD processes

AlN, Si3N4, SiO2, Al2O3 (Others and metals to be released)

Processing temperature

Up to 350 °C

Liquid source lines

4

Plasma gas lines

N2, O2

Plasma pretreatment

Yes

Ammonia (NH3) gas line

Optional

Ozone gas line

Optional

Process control

Recipe-based; fully configurable