Home of ALD

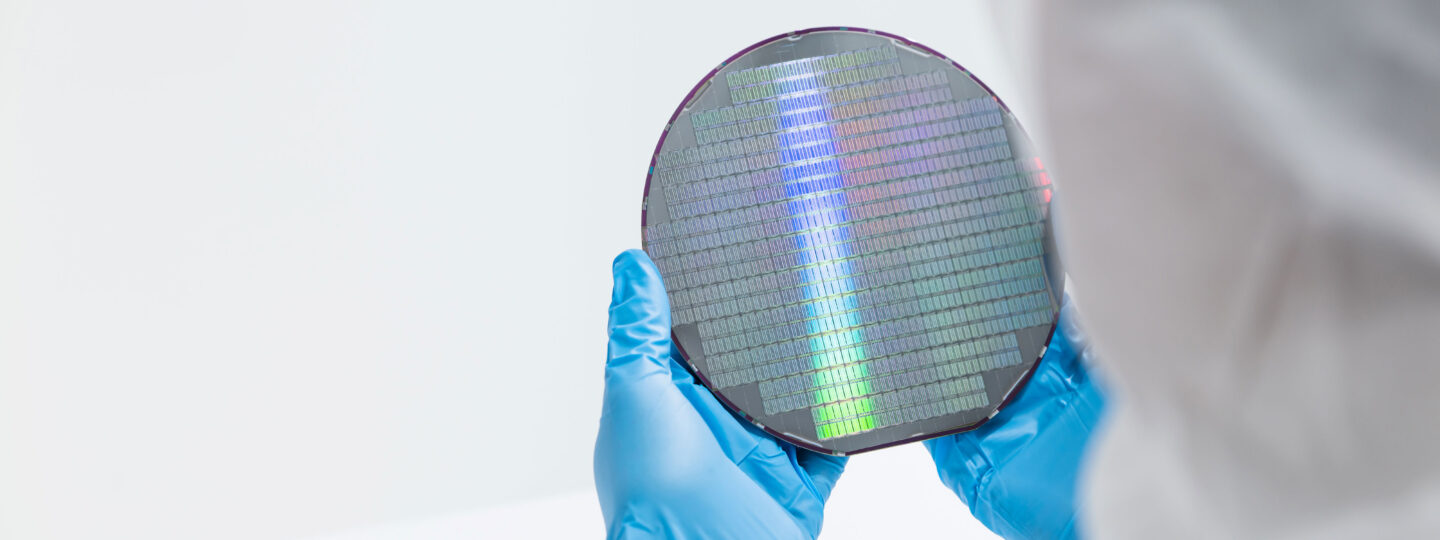

In 1984 we started the world’s first industrial production using atomic layer deposition (ALD). Today, Beneq is the most recognized provider of ALD equipment and R&D services. Our mission is to create premium tools for production and for research, and to enable technology mega trends through industrial ALD solutions.

Products

Find your tool

Batch Production

Largest scale, general purpose ALD production systems ideal for coating diverse substrate types and thick films.

Read moreSpatial ALD

Large-area, roll-to-roll atomic layer deposition systems for flexible substrates in R&D and production.

Read moreServices

Our expertise at your service

Coating service

The fastest way to market with a new ALD solution is to outsource the production to Beneq. Beneq coating services is a great way to explore the high-performance ALD technology and thin film coatings with a low threshold and limited risk.

Read moreR&D service

If you want to improve your products with Atomic Layer Deposition and ALD services, selecting the right partner is easy: Beneq brings you over thirty years of thin film experience and the world’s largest ALD-dedicated production facility.

Read more