Liquid source line with boosting functionality LS-BL

For low vapour pressure liquid precursors (BTBAS, 3DMAS, TEGA, etc.)

Includes:

- two pneumatic pulsing valves: one for purge gas, the other for chemical supply

- high precision needle valve for pulse adjustment

- orbital welded stainless steel tubing with VCR® (Swagelok) fittings

- aluminum liquid source container holder cooling cup for controlling the source temperature between +5 °C and room temperature (requires cooling water assembly, chiller or facility cooling lines)

Please note that this option does not include a precursor container.

Liquid source precursor containers LS-BL-PC/200 and LS-BL-PC/200 DOT

Additional liquid source containers.

- for water (H2O), trimethyl aluminum (TMA), diethyl zinc (DEZ), titanium tetrachloride (TiCl4) etc.

- volume 200 ml, maximum filling volume 150 ml*

- equipped with two separate lines with manual valves

- material: stainless steel

- LS-LS-BL-PC/200 : for H2O, TMA, DEZ, TiCl4 etc.

- LS-BL-PC/200 DOT : for H2O, TMA, DEZ, TiCl4 etc., DOT* certified

*) Department of Transportation (USA)

Liquid source line with single output line LS-SL

For H2O, TMA, DEZ, TiCl4 etc.

Includes:

- pneumatic pulsing valve

- orifice for pulse adjustment (high precision needle valve available as an option) orbital welded stainless steel tubing with VCR ® (Swagelok) fittings

- aluminum liquid source container holder cooling cup for controlling the source temperature between +5 °C and room temperature (requires cooling water assembly, chiller or facility cooling lines)

Please note that this option does not include a precursor container.

Liquid precursor source, single line design LS-SL

For high vapour pressure precursors (H2O, TMA, DEZ etc.)

Includes:

- two pneumatic pulsing valves,

- high precision orifice for dose adjustment,

- stainless steel tubing with VCR connectors

- cooling cup for liquid source container

Liquid source precursor container LS-SL-PC/200, LS-SL-PC/200/H2O and LS-PC/200/DOT

- additional containers

- volume 200 ml, maximum filling volume 150 ml

- three different container types for different chemicals

- LS-PC/200/H2O for H2O and other non-toxic and corrosive chemicals

- LS-PC/200 for H2O, TMA, DEZ, TiCl4 etc

- LS-PC/200/DOT for H2O, TMA, DEZ, TiCl4 etc, DOT* certified

- using separate containers for different precursors prevents cross contamination

- containers are equipped with output line with manual valve

- convenient filling port for adding chemicals

- material stainless steel

*) Department of Transportation (USA)

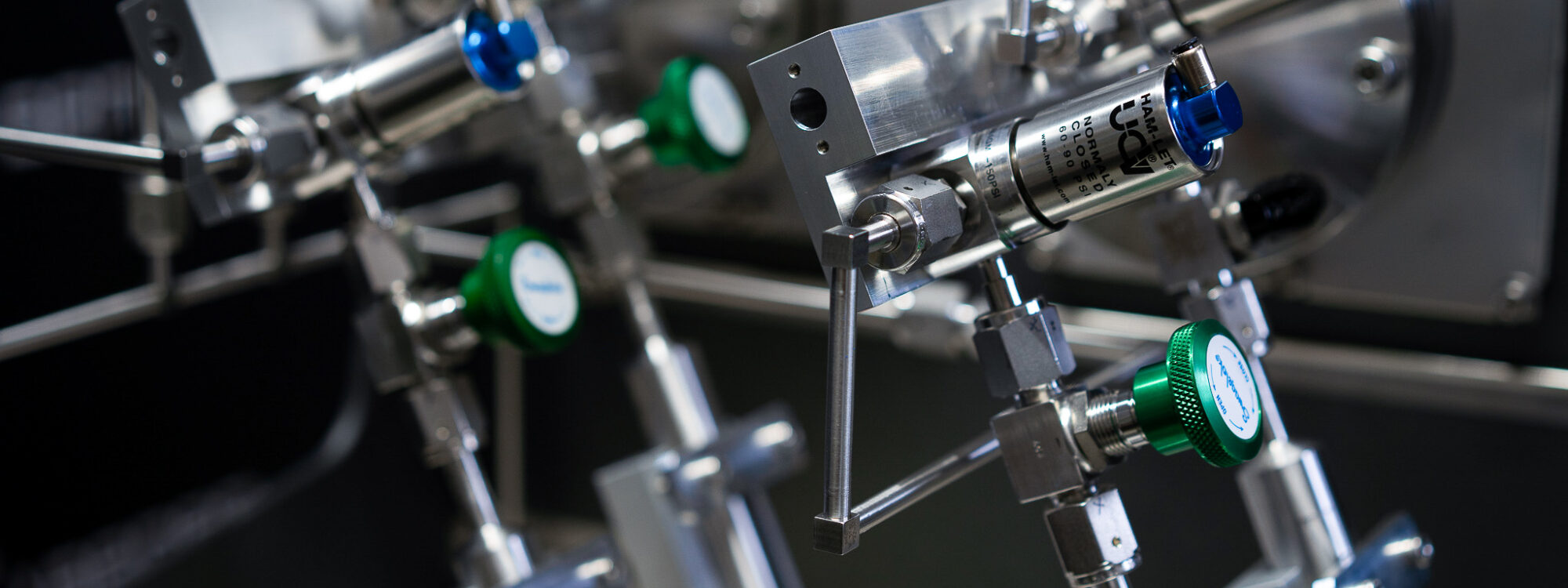

Liquid source pressure transducer LS-PT

For monitoring liquid source pulsing.

- useful for preventing running out of precursors during runs

- specifically useful for process development

- compatible with both LS-SL and LS-BL source line configurations

- Pressure range 0 – 100 Torr.

Needle valve for dose adjustment NV-HP

Replaces the orifice in the standard single-line liquid source.

- allows easy, high precision dose adjustment during process tuning

- for new chemistry depositions

- adjustable flow range