SEMICONDUCTOR EQUIPMENT PART COATING

Supplying superior purity, conformality, and etch resistance with ALD

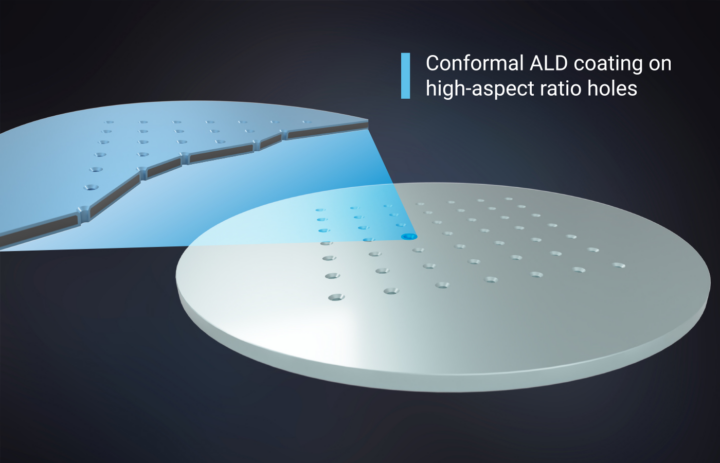

Full protection from metal and particle contamination during semiconductor processing demands high purity coatings. ALD produces dense, pinhole-free anticorrosion coatings, perfect as an option for semiconductor OEMs over anodization and plasma spray.

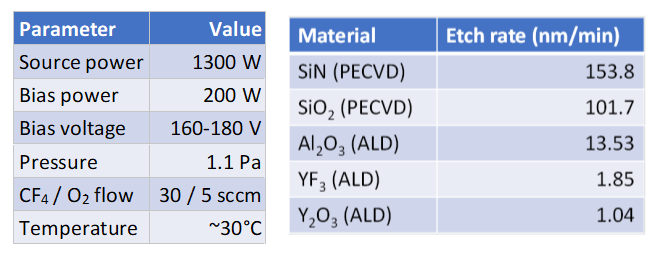

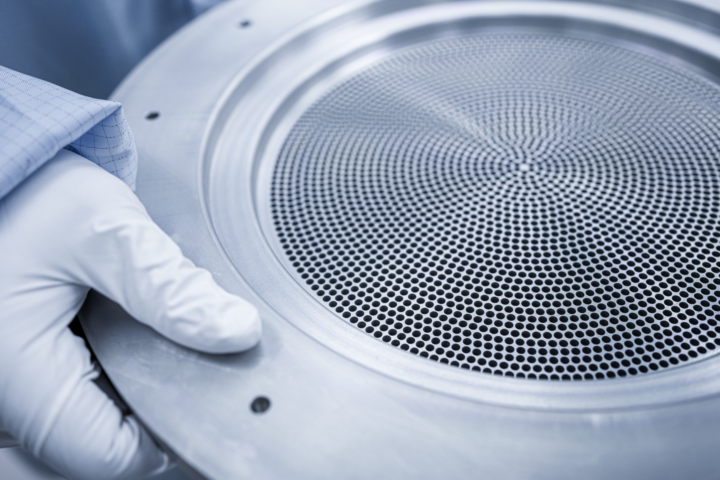

Higher purity, higher yield. ALD-coated parts, like showerheads, liners, and chucks, produce fewer particles and less metal contamination compared to anodizing, PVD or plasma spray. The unparalleled conformality and uniformity of ALD allows even complex and high-aspect ratio parts to be coated with high quality films. For semiconductor manufacturers, this offers an effective anti-corrosion coating solution that yields longer part usage and faster recovery after maintenance. Your team will appreciate improved process stability and higher tool uptime.

Robust part protection using ALD. Production requirements in the semiconductor manufacturing industry are some of the strictest. With ALD-coated chamber components, you can be confident your parts and substrates have the highest quality protection. Anticorrosion coatings by ALD offer:

- Low particle generation

- Low metal contamination

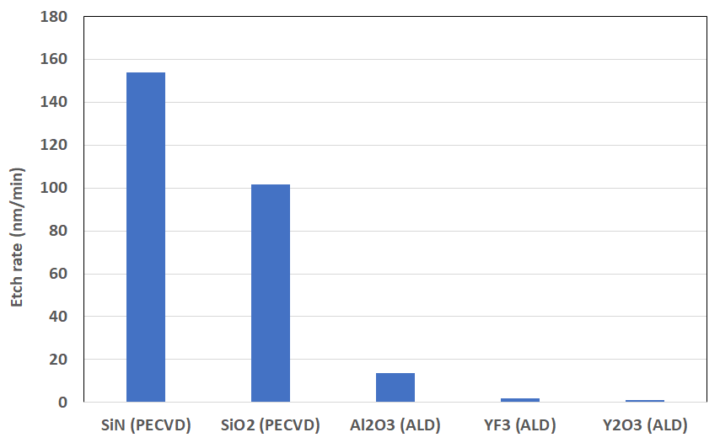

- High etch and sputter resistance

- Conformal coatings in high-aspect ratio holes and structures

- Batch coating capability

The ideal industrial ALD solution for coating critical chamber components. Successful coating of parts by ALD requires the correct chamber configuration for the part. The Beneq P800 is the most versatile commercially available ALD reactor with the largest selection of reaction chambers to match your production needs. Choose from our standard chamber sizes and substrate holders or allow us to customize a configuration for your specific parts. At Beneq, we offer the capability for Al2O3, Y2O3 and various other ALD processes for single part and batch coatings. Our thin films are purity tested and our manufacturing ISO quality certified.

Rigorously tested and validated. Have confidence knowing exactly what you are getting from our solutions.Beneq’s ALD film properties for anticorrosion applications meet or exceed specifications by global OEMs.