Wafer Fab Equipment

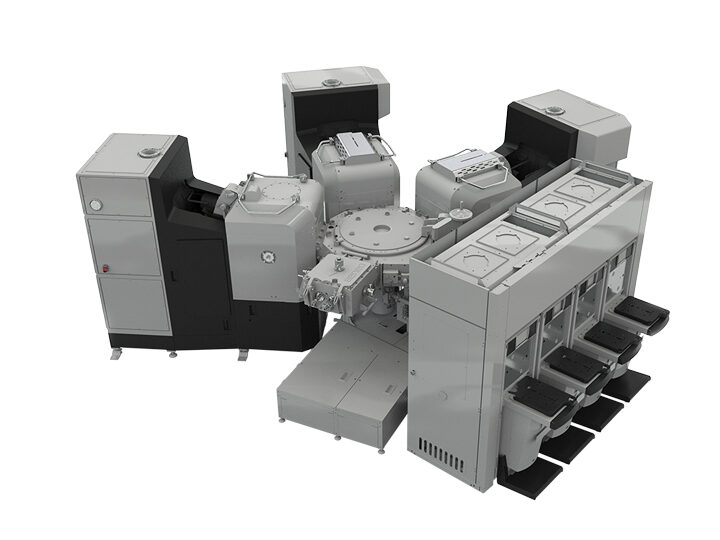

Beneq Transform® 300

The most versatile ALD cluster tool for 300 mm wafer production

EQUIPMENT

Maximum Configuration

3 processing modules & 1 preheater

Preheating capability

Yes

Transfer module

M2C5

Cooling option

Built-in

Substrate loading

EFEM

Substrate size

300mm with 200mm bridge capability

Substrate

Si, Glass, and Others

Dimensions

4400 x 4800 x 2250 mm

Host Integration

SECS/GEM

THROUGHPUT

Al2O3–300°C–50nm

12 wafers/hour – 1 PM

ALD BATCH PROCESS MODULE

Batch size

Up to 25 x 300 mm wafers

Safety standards

SEMI S2 and S8

ALD processes

Al2O3, HfO2, Ta2O5, TiO2, SiO2, ZnO, AlN, TiN

Processing temperature

Up to 420 °C

Liquid source lines

3+1 (optional)

Ammonia gas line

Optional

Ozone gas line

Optional

Process control

Recipe-based; fully configurable

ALD PLASMA PROCESS MODULE

Single wafer

300mm with 200mm bridge capability

Safety standards

SEMI S2 and S8

ALD processes

AlN, Si3N4, SiO2, Al2O3

Processing temperature

Up to 350 °C

Liquid source lines

3+1 (optional)

Plasma gas lines

N2, O2, H2(optional)

Plasma pretreatment

Yes

Ammonia gas line

Optional

Ozone gas line

Optional

Process control

Recipe-based; fully configurable