ANTIREFLECTION COATINGS

Beneq AtomGrass™ Antireflection Coating

Minimal reflection, broadband coverage and wide-angle performance makes Beneq AtomGrass™ a powerful antireflection coating solution for complex, emerging optics.

WHAT IS BENEQ ATOMGRASS™?

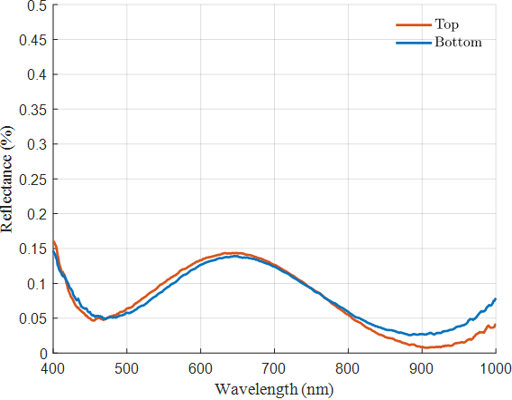

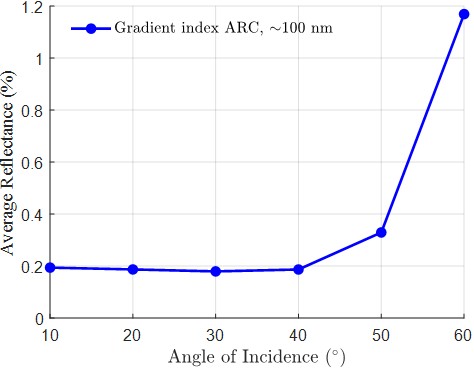

Beneq AtomGrass™ is a gradient-index antireflection coating fabricated using Atomic Layer Deposition. This optical coating is engineered with grass-like nanostructures to allow a smooth decrease in the material’s index of refraction from the surface to substrate interface. This provides antireflective performance across a large range of wavelengths and at wide angles of incidence.

Average Reflection Minima

0.1%

Wavelength Range

380 – 1050 nm

Angle of Incidence

Up to 50°

Combined with a traditional optical stack, Beneq AtomGrass™ offers excellent performance in 3 critical categories. By tweaking the deposition parameters, the reflection minima and wavelength range can be tuned for specific applications.

Wide-angle Antireflective Coatings

Learn about how gradient-index antireflection coatings fabricated with ALD exhibit wide-angle performance and why this is important for modern optical systems.

Read more about Wide-angle Antireflective Coatings >

WHY USE ATOMIC LAYER DEPOSITION FOR ANTIREFLECTIVE COATINGS?

Precision: When fabricating ARCs, depositing the correct thickness is extremely important. Small differences in material thickness could compromise the performance of the interference coatings by causing incomplete destruction or, in some cases, even constructive interference in some cases. ALD grows materials 1 Angstrom at a time, giving nanometer resolution thickness control.

Tunability: Material properties are highly tunable with ALD. By tweaking deposition parameters, like temperature or plasma power, properties like index of refraction and extinction coefficient can be changed. Even further tunability is possible with engineered materials and doping. This can result in high control of the reflection minima and bandwidth of the resulting ARC.

Purity: Films made with ALD have very low percentage of contaminants. Ultra-low impurity level allows negligible absorption and volume scattering.

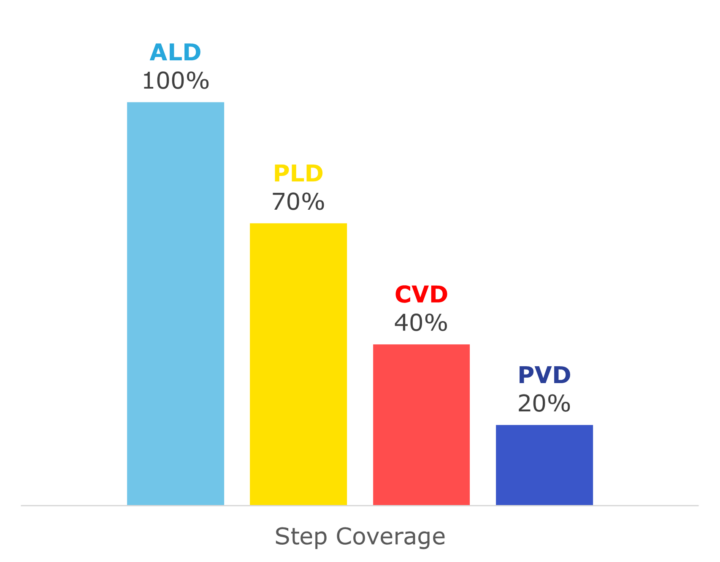

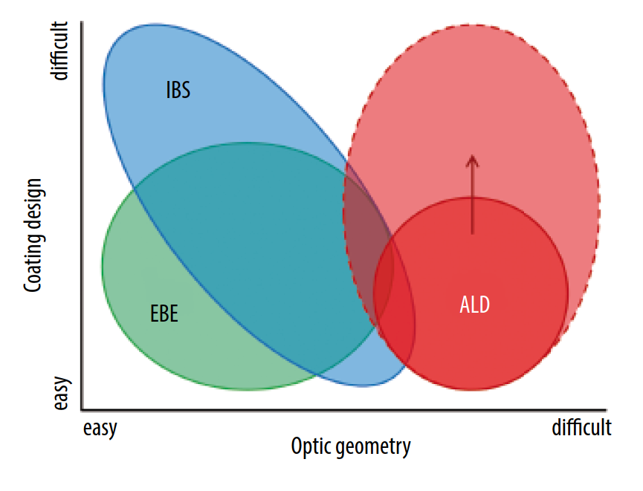

Conformality: As optics geometries become smaller and more complex, the need for consistent properties across the entire surface become vital. Isotropic ALD processes provide perfectly conformal films on complex geometries from the micro to the macro scale. This is extremely important for applications where PVD struggles to provide uniform films, like on aspheric lenses or waveguides.

BENEQ ATOMGRASS™ APPLICATIONS

Mobile Camera Lens Coating

Today, nearly all photos are taken on smartphones, resulting in mobile phone camera quality becoming a key selling point of mobile devices. As cameras continue to miniaturize and improve, lens design and element structures inevitably become more complex. ALD offers robust manufacturing solutions for antireflective coatings on next-generation mobile camera lenses.

Read more about Mobile Camera Lens Coating >

Automotive Camera Lens Coating

For autonomous vehicles (AVs) using cameras, lens flare is a major cause of artifacts and ghost images, potentially leading to catastrophic consequences. Learn about how gradient-index antireflection coatings fabricated with Atomic Layer Deposition can reduce lens flare and increase the safety of automotive camera modules in AVs.