High-performance AR coatings for mass production

Ever since we earlier this year announced the licensing of rotary spatial ALD technology and launched Beneq R11, our new rotary tool for plasma enhanced spatial ALD, we have received a steady flow of inquiries and questions about where we see the new equipment being the most useful. Plenty of things, we might say, but here is one prime example: fast low temperature optical coatings, such as anti-reflection (AR) coatings on polycarbonate.

The rotary spatial ALD technology and the Beneq R11 equipment solve two major challenges that have until now been associated with the use of ALD in optical coatings in high-volume manufacturing: the deposition rate and the deposition temperature. The new advanced spatial ALD technology has several advantages over traditional PVD coatings commonly used for optical coatings.

Ultra-fast ALD deposition rates with Beneq R11

Atomic layer deposition is well known for great thin film quality, but the low deposition rates of traditional ALD methods have prohibited its use in volume production. With Beneq R11, this is no longer an issue as we can reach deposition rates of over 1µm/h with common optical materials such as SiO2 and TiO2. This takes the technology from lab scale to high volume manufacturing in one giant leap. Some might even call the deposition rates revolutionary.

Lower deposition temperature for polymer substrates

Beneq R11 is the first ALD reactor that offers plasma-enhanced ALD (PEALD) with high throughput. One of the main benefits of PEALD is that it permits lower deposition temperatures than thermal ALD. This widens the application area to materials that do not tolerate high process temperatures.

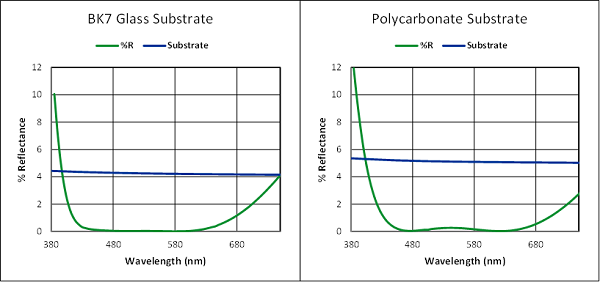

For optical coatings in particular, the new deposition process at temperatures below 100°C enables the use of SiO2 as the low index material on polymer substrates, such as polycarbonate. This is especially important for anti-reflective (AR) coatings, where the low index material needs to have a refractive index below 1,5. The new rotary spatial PEALD system frees us from the earlier limitation of Al2O3 as the only low index ALD material available for polymer substrates. This too is a major change.

The new ALD process beats PVD in many ways

Most of today’s multi-layer anti-reflective coatings are created with Physical Vapor Deposition (PVD) methods such as sputtering, evaporation, ion-assisted deposition (IAD) or ion beam deposition (IBD). ALD has some significant advantages over all of these technologies. To name a few:

- Coating quality – ALD coatings can be applied on items of non-planar surface geometry with excellent uniformity, step coverage and conformality.

- Vacuum level – The Beneq R11 process pressure is around 1 torr or 1 mbar whereas the common PVD systems operate at pressures that are several orders of magnitude lower. With ALD, the pump-down is faster, pumps are much cheaper and the time-consuming baking step is completely eliminated.

- Repeatability – The ALD process is highly repeatable by nature. As the ALD process relies on saturating surface reactions, the film thickness control is achieved simply by calculating the number of cycles (in the case of the rotary equipment, the number of revolutions). This greatly reduces the need for in-situ process controls and adjustments, making it easier to ensure constant high performance and high yield for optical coatings produced in large batches.

- Shorter batch times – Beneq R11 uses a batch coating process, capable of coating of 10 pieces of 200 mm wafers or over 400 pieces of one-inch wafers in each batch. Typical batch times are shorter than with PVD alternatives, thanks to the high deposition rate and the short pump down and heating times. Actually, it has happened that the Beneq R11 batch has already been finished when a PVD system is still in the pump down phase and hasn’t even started the actual coating. This naturally means higher production capacity.

- Lower cost of ownership – Despite all its extra benefits, Beneq’s rotary spatial ALD equipment is more affordable than the complex PVD systems. The precise coating process also ensures low material costs for typical optical coating materials, such as SiO2 and TiO2.

Beneq has the right ALD equipment for all optical coatings

As anybody, who has been struggling with the low capacity of older ALD equipment or quality and time restrictions of PVD-based optical coating processes, knows, this is pretty exciting stuff. Even we at Beneq, as pioneers with more than 15 years of experience of ALD for optical coatings, are thrilled to see the results.

If you are looking for a more traditional ALD tool for smaller volumes of optical coatings, the right solution may be Beneq P400A, which has been used for a variety of demanding optical coating solutions for years.

Whichever equipment you find the most interesting, we would be delighted to tell you more and assist with any questions related to ALD and optical coatings. ALD-based optical coatings for high-capacity production are finally here!