Blog

Improving Curved uOLED encapsulation with ALD

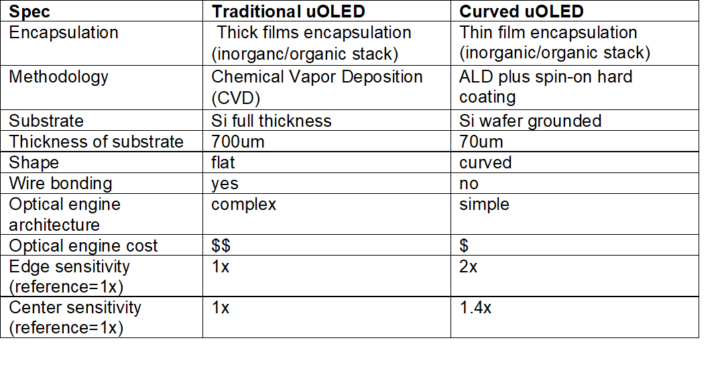

Pinhole free encapsulation with ALD enables simpler micro-OLED manufacturing and robust protection. The thinner ALD encasement enables substrate bending and opens up the possibility of more compact, curved devices.

Think ALD, think pinhole free.

For the past decades, organic light emitting diodes (OLEDs) have become of great interests for applications to micro-displays. Unfortunately, these systems are highly sensitive to moisture and oxygen ingress and require high barrier encapsulation. Additionally, a specific protection needs to be added to protect the device from mechanical failure. Depending on the application, various options from glass lids to flexible barriers have been developed. The former offers high mechanical protection but suffers from long implementation processes, while the later typically exhibit low hardness and poor wear resistance.

ALD for leading edge curved micro displays

Micro-displays are typically fabricated as flat image‐generating surfaces. Obviously, they generate a flat image that must be transformed into a curved image wave‐front representation for projection into the eye. Flat image sources force the design and use of complex eyepiece optics that efficiently collect and convert the flat image into a curved field‐of‐view optimized to the human eye. Unfortunately, large footprint, high weight, and extensive display optics sometimes prevent the integration of micro-displays into applications where weight and space are critical parameters for the system to be adopted in the consumer market.

A closer look at the data

The afore mentioned reliability issues of OLED micro-displays stemming from oxygen and water ingress can be addressed by using thin-film multilayer encapsulations made by alternating thin inorganic ALD barrier layers with thicker polymer matrix for mechanical protection.

A thin Al2O3 layer deposited by low temperature ALD (< 100 °C) directly on top of the OLED structure serves as sealant. A thicker hard coating grown on top of the ALD provides mechanical protection. The result is broadly equivalent to CVD plus organic sealant without the drawbacks of poor conformality or pinhole susceptibility. The end result is a significantly thinner encapsulation stack.

The two-barrier layer combination, enhances the resistance of the OLED stack to atmospheric moisture, provides mechanical protection against abrasion and enables flexibility

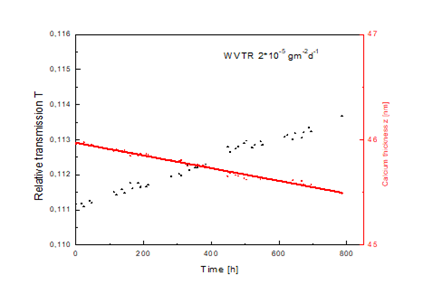

As a reference, Figure 1 below represents the typical performance of the standard encapsulation scheme using a fully encapsulated sample with a glass lid.

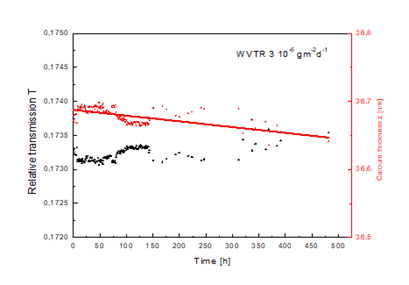

To address the issue of encapsulation and impermeability, Beneq scientists have been studying and testing ALD coatings and have demonstrated the ability to deposit metal oxides fully pin-hole free. For comparison, we show on Figure 2 a sample with only an ALD encapsulation consisting of a laminate stack 100 nm thick capable of achieving even better encapsulation than the glass enclosure method.

The inorganic ALD films clearly show the ability to encapsulate below the detection limit for most commercial WVTR-measurement systems and offer an ideal solution to the OLED sensitivity to moisture and oxygen degradation. We are left with the requirement of protecting the ALD film against mechanical wear, which maybe be solved through an additional layer of spin-on acrylic or similar organic compound.

Bringing micro-displays to augmented reality (AR) with ALD

The real trick to achieving miniaturization and reducing system complexity is to keep the micro-display stack as thin as possible while maintaining the required water and oxygen transmission rates. ALD helps to achieve this purpose in two ways. First is via encapsulation with a pin-hole free coating, and second, by keeping the stack as thin as possible. A second hard coating is necessary for mechanical protection of the ALD layer, and typically this is done by a polymer layer of a few micron thickness. This allows for further thinning of the device through grinding which enables the curvature with similar yields as of flat glass encased OLED micro-displays. The result is an AR display with a much lighter optical engine and as much as double the sensitivity at the edges.