OPTICAL COATINGS

ALD coatings for spherical domes

Atomic Layer Deposition for 3D Optical Coatings

ALD enables high quality optical coatings on high curvature optics

The challenge when coating 3D optics is to deposit the coating with high uniformity over an arbitrary topology in a simple manner. The common techniques used for optical coatings, including magnetron sputtering, evaporation, electron beam evaporation (EBE) and ion beam sputtering (IBS), all so called line-of-sight methods. This leads to a non-uniform thickness distribution and shadowing effects. To reach a high level of conformality on 3D shapes for example, effort needs to be made to specifically twist, turn, rotate or otherwise move the substrates. This comes with an extensive load of mechanical work and process optimization and requires tight control of the process parameters. In the end, this may still not lead to a sufficiently homogeneous film deposition. ALD overcomes those constraints and has proven its suitability for high precision pinhole free films, where the challenge is not only to achieve uniformity over a large scale, but to coat conformally over high aspect ratio structures. Additionally, the ALD technology has reached a high level of reliability, making it a superior alternative for mass production of critical optical coatings. In this technical blog we describe how ALD can be utilized for coating high curvature optics using optical domes as an example.

Why the ALD coatings outperform the alternative methods

Beneq’s ALD coatings on highly curved lenses works well. The obtained AR-effect extends from the visual into the infrared range even in case of dome shaped lenses with a radius as large as 150 mm. The method has been found suitable for a multitude of optical components, not just lenses. Beneq’s experience on multi-layered coatings on 3D lenses reveal the optimized AR effect and enhanced optical properties during the fabrication of antireflection coatings via nanostructured layers. The resulting optical stack features combinations of classical optical interference coatings typically up to fifty layers. Each wavelength structure with a thickness of anywhere from a monolayer to tens of nanometers has been generated through commercial optical modeling software. Beneq’s batch tools such as the Beneq P400A and Beneq P800 increase the applicability of this technology and subsequently enable the applicability of this technology to high volume manufacturing.

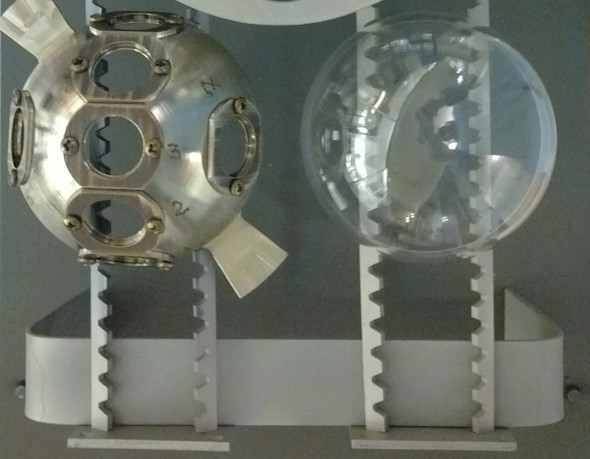

Practical example: ALD on large domes

Let’s take a specific example. In the figure above we show an example of the type of work done at Beneq. For a challenging 3D structure such as the dome shown above, we begin by running simulations to get an idea of the ALD stack needed to duplicate the spectral response required. The next step is to evaluate the various layers on test structures to get the right thickness and uniformity for every single one of those layers. Beneq has been able to achieve uniformity on quartz flats on a jig with a diameter as large as 150mm with a maximum deviation from spec of 2.5% for the most difficult oxide. This is the worst condition as precursor chemistry plays a significant factor in achieving a uniform coating. For a different oxide, the uniformity was less than 1%, yielding an overall calculated deviation from design of 1.6% over a 1 um coating. Depending on the design specifications, which sets the choice of the ALD layers, Beneq has completed designs of anti-reflective coatings with excellent spectral responses from 400nm to 2500nm. Depending on the requirement from the customer, the coating on the dome maybe be single or double sided.

Although further research and developments on the chemistry side continue, ALD is a proven method for depositing optical thin films that can be easily adapted to complex formed optical components due to the very good conformality of ALD coatings. At Beneq, Home of ALD, we have the experience to implement single and multilayer coatings for individual or multiple samples. Naturally, Beneq has the largest cleanroom of its kind to help customers transition from experimental to large scale production, all under the same roof.