Superconducting materials are integral to the next generation of quantum computing and advanced electronics. However, producing ultra-thin superconducting films with the required precision and cost-efficiency has been a persistent challenge. Beneq addresses this with a distinct approach – delivering high-performance superconducting TiN films using thermal ALD and TiCl₄ precursor, as a cost-effective alternative to the plasma-enhanced ALD (PEALD) methods commonly used in the field.

Superconducting materials are integral to the next generation of quantum computing and advanced electronics. However, producing ultra-thin superconducting films with the required precision and cost-efficiency has been a persistent challenge. Beneq addresses this with a distinct approach – delivering high-performance superconducting TiN films using thermal ALD and TiCl₄ precursor, as a cost-effective alternative to the plasma-enhanced ALD (PEALD) methods commonly used in the field.

This innovation enables superconducting behavior in thin-film TiN deposited by thermal ALD, with a transition temperature that onsets at 3.80 K and stabilizes at 2.50 K. The process also reduces equipment complexity and operational cost compared to plasma-based methods, supporting scalable, cost-effective superconducting applications. 1

Why Precision Matters in Superconducting Films

Superconducting applications require atomic-level control over film properties. Conventional deposition techniques often lack the precision and uniformity necessary to meet these demands. ALD resolves this by offering:

- Atomic-level thickness control to fine-tune superconducting properties

- Excellent uniformity and conformality across complex 3D structures

- High-purity film growth to minimize contamination and defects

- Industrial scalability via a mature and controllable process

Advantages of Thermal ALD for TiN Superconducting Layers

Using Ossila Four- Point Probe; TiN RT Resistivity 100 − 400 µΩ cm 2

While many established processes for superconducting TiN films are based on plasma-enhanced ALD, Beneq has demonstrated that thermal ALD with a TiCl₄ precursor offers significant advantages:

- Reduced equipment and process complexity

- Lower operating costs

- Minimized risk of plasma-induced surface damage

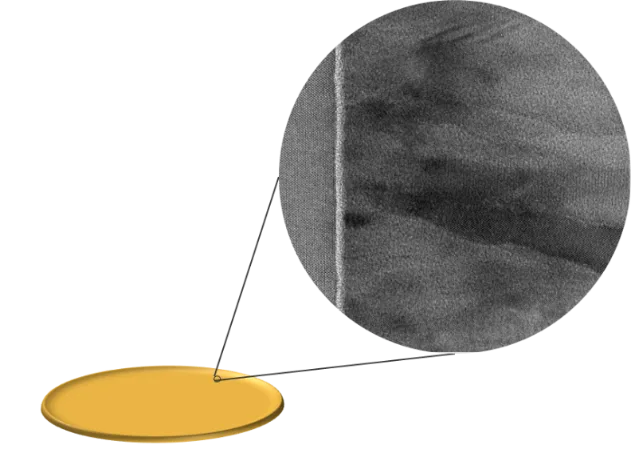

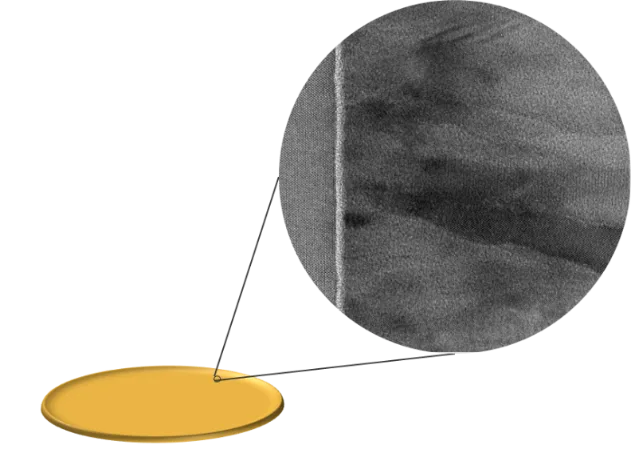

JIB 4700F JOEL; TiN with Polycrystalline Structure

Implemented on the Beneq TFS 200 reactor, this process produces TiN films with low resistance, superior uniformity, and superconducting performance that compares favorably with other film layers developed using plasma-enhanced ALD techniques.

Validating Superconducting Behavior

Beneq validated the superconducting performance of its TiN films using two independent measurement techniques:

- Physical Property Measurement System (PPMS) identified a transition temperature (Tc) onset at 3.80 K, stabilizing at 2.50 K, confirming a consistent superconducting phase

- Vibrating Sample Magnetometer (VSM) was used in field-cooled (FC) mode to detect the Meissner effect, a hallmark of superconductivity

Together, these results confirm the high-quality, superconducting characteristics of the TiN films and demonstrate their applicability in quantum-grade environments.

Where This Technology Can Be Applied

This TiN ALD process supports key applications such as:

- Quantum computing, where uniformity and low defect density enhance qubit performance

- Microelectronics and sensors, enabling faster, lower-loss signal pathways

- High-performance coatings, relevant to aerospace, automotive, and precision manufacturing

It also provides an effective research platform for exploring superconducting and superinsulating materials.

Who May Be Interested in This Solution

The process is designed for:

- R&D professionals in quantum materials and device physics

- Semiconductor manufacturers developing quantum and superconducting technologies

- Process engineers seeking scalable, high-uniformity deposition techniques

Exploring the Next Steps

If you are interested in evaluating this thermal ALD process for superconducting TiN films, we invite you to get in touch to discuss collaboration opportunities. Testing is typically performed on low-resistivity substrates, and we are happy to advise on suitable materials for your application.

In parallel with this offering, we are also developing a more uniform plasma-enhanced ALD (PEALD) TiN process aimed at achieving higher transition temperatures, reducing deposition temperatures, and further enhancing film uniformity. Whether you are assessing near-term integration or exploring future possibilities, we welcome the opportunity to support your R&D and production goals.

1 As an industry reference, bulk single-crystal TiN has demonstrated a transition temperature of up to 6.0 K, highlighting the upper performance benchmark for TiN-based superconductors.

2 (Torgovkin, Andrii, et al. “High quality superconducting titanium nitride thin film growth using infrared pulsed laser deposition.” Superconductor Science and Technology 31.5 (2018): 055017.)

About the Authors

Sanaz Zarabi, PhD, Process Development Engineer

Sanaz Zarabi, PhD, Process Development Engineer

Sanaz specializes in ALD technologies and thin film applications across optics and energy, with a strong background in materials science and applied physics.

Zahra Ahaliabadeh, PhD, Process Development Engineer

Zahra Ahaliabadeh, PhD, Process Development Engineer

Zahra is a specialist in thin-film technologies with applications in semiconductors and advanced energy systems. She holds a PhD in Chemistry and has a strong background in materials science and process integration.

Sanaz Zarabi, PhD, Process Development Engineer

Sanaz Zarabi, PhD, Process Development Engineer  Zahra Ahaliabadeh

Zahra Ahaliabadeh