Did you know this about conformal coatings?

Electronic components and devices do not tolerate hot and humid conditions. Most people know this and avoid exposing electronics to vapors and liquids.

But we all know that sometimes humid things just happen: phones fall into toilets from shirt pockets, swimming suits are accidentally put in the same bag with a computer, equipment is forgotten outside in the rain…

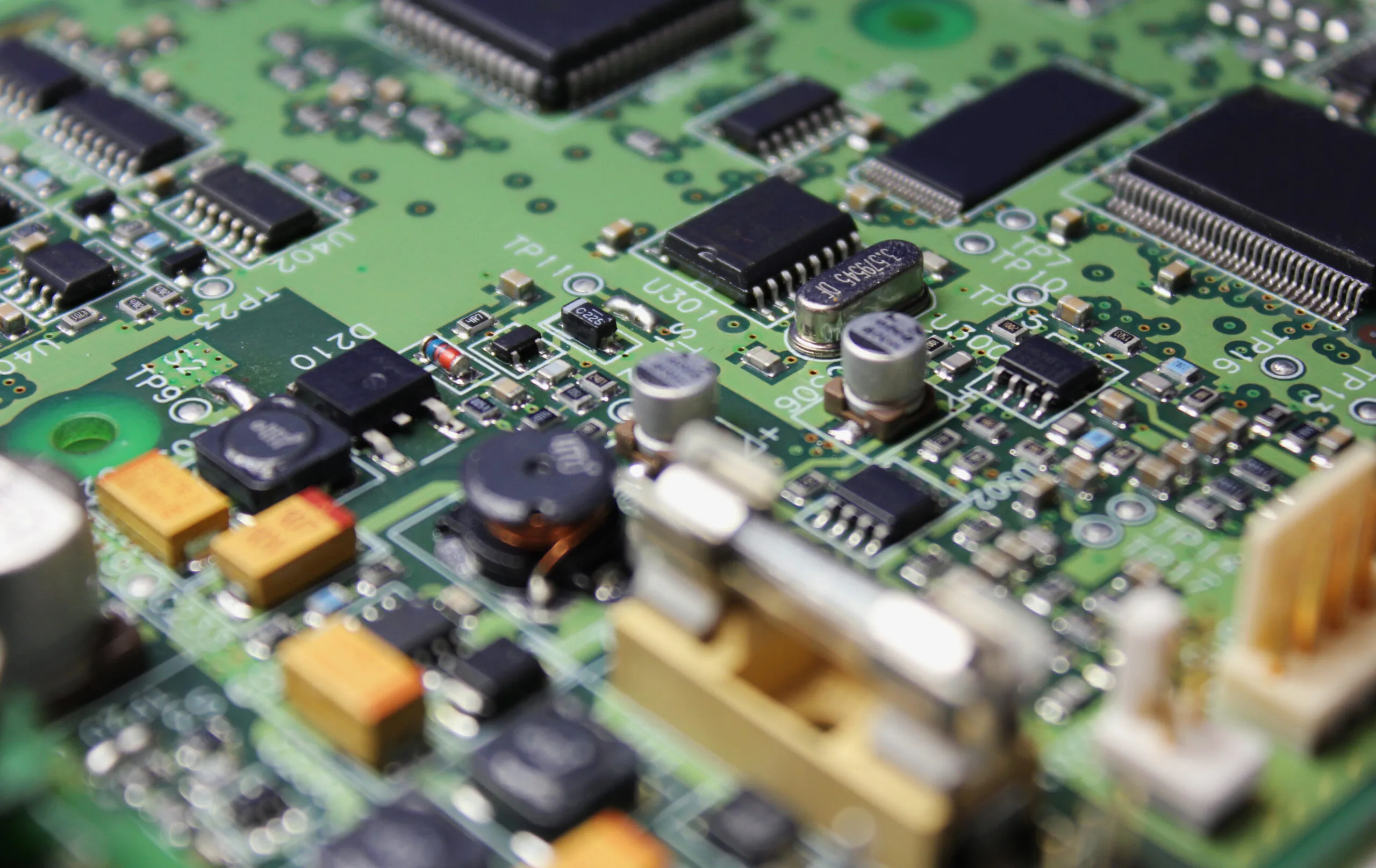

This is why companies across many industries struggle to provide moisture and corrosion protection for printed circuit boards and electronic components.

A perfectly sealed enclosure is in practice impossible to create

The trend of tighter integration requirements and the increasing number of sensitive components in electronic devices make the task of moisture protection all the more challenging. Extensive packaging and enclosure solutions increase complexity and raise the bill of materials of electronics products.

Over time, even tight sealing will start leaking and lets humidity through. Sometimes moisture can be trapped in the enclosure during manufacturing. In tough conditions, condensation will result in moisture inside devices. When moisture reaches sensitive components, they will start to corrode, and will eventually short-circuit and become inoperable.

PCB’s require extra moisture protection

Water resistance of critical components gives longer product lifetime and long product life gives competitive advantage.

Most people working with electronics know that and try to improve the reliability of electronic systems with some kind of sealing, PCB coating or component encapsulation. A bagful of sprays, lacquers and coating fluids are applied to circuit boards every day – often with mixed results.

Many of the silicone compounds and parylene coatings that are used today in the electronics industry to protect components from moisture damage fall short in demanding conditions. Solutions which are marketed as conformal coatings leave small holes in the coating and need to be applied in very thick layers to provide true vapor barriers.

If you have experience from working with extremely moisture sensitive electronics, such as OLED panels, you probably know that too.

Atomic Layer Deposition offers the ultimate conformal coating

ALD barrier films are ultrathin, pinhole-free and totally conformal. ALD alone or in combination with other coating technologies can drastically improve moisture resistance and allow electronic devices perform reliably under challenging conditions.

As we demonstrated in our earlier blog post A Billion times better a moisture barrier, the difference in WVTR values between the common moisture protection alternatives and conformal coatings deposited with ALD is huge. There are also areas where conventional CVD coatings are not enough or not possible at all. This is the case for example with increasing the shelf-life of sensitive powder materials.

You can get moisture protection as a service from Beneq

To lower the threshold of testing ALD-based conformal coatings, Beneq offers moisture protection and encapsulation as a service. It is a great way to explore this high-performance humidity protection technology.

We already have many customers who have taken the first steps with us using our ALD-123 R&D process, which provides an easy step-by-step approach from first samples towards production readiness of the barrier coating. The process has clear milestones and deliverables for each phase, resulting in well-managed R&D projects with predefined budgets.

Outsourcing thin film R&D is the fastest way to market

Beneq has implemented more ALD applications than any other company. Our development services team already have a large number of success stories with companies in a variety of business areas, from defense and aerospace to medical and consumer applications. The examples range from protection of sensitive electronics components in consumer electronics to efficiency improvements of advanced automotive parts and encapsulation of flexible electronics.

It is also possible to outsource the whole production of moisture barriers to Beneq Coating Services. This makes sense if you want to get the best available conformal coating for your electronics without initial captial investments.

If you want to know more, you can view some of our customer cases (for example OLED encapsulation, Roll-to Roll barrier films for flexible OLED and moisture barriers for scintillators) for conformal thin film coatings on our Applications pages. And you can always turn to our experts to learn more about how you can outsource your barrier R&D, thin film coating development and ALD manufacturing to our teams at the Beneq barrier factory, the Home of ALD.