Industrial use of atomic layer deposition: Moisture barriers

In a blog post a couple of weeks ago, we mentioned that we are often asked to explain what our ALD equipment can be used for. In this post, we will give a couple of examples more. This time we will talk of an industrial ALD application that is quite common and can take many forms: moisture barriers.

Many devices in today’s digital, electronic world don’t much like water and humidity. If you are trying to protect large, flat and smooth things that don’t have high protection requirements, moisture barriers are relatively easy to achieve – just cover the surface with a protective sheet or spray it with moisture protection and you are done. It is a little bit like, say, applying insulation paint on a bathroom wall.

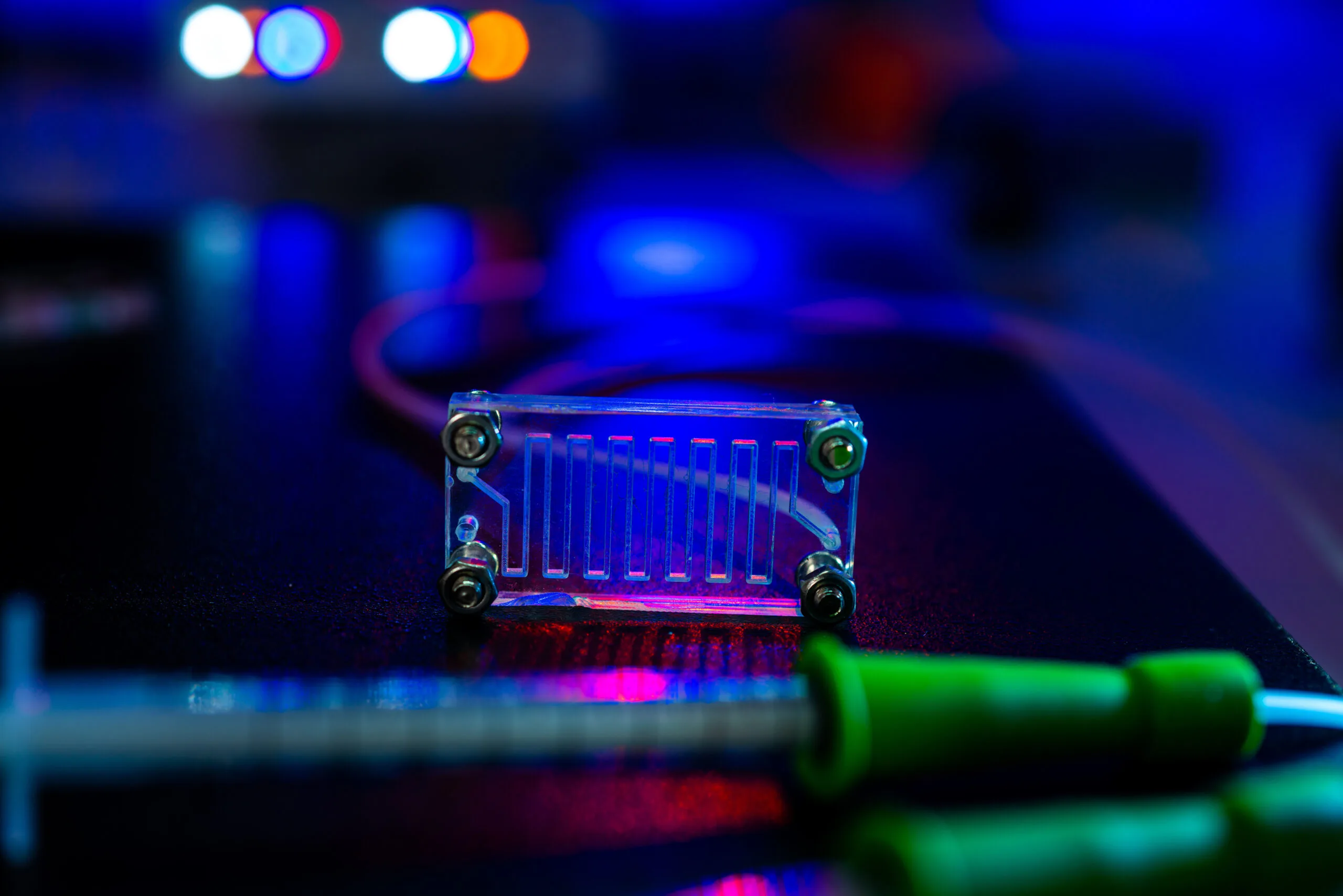

Sometimes, however, the spaces between the surfaces to be protected are so tiny and condensed that there is no way to paint or spray a coating. The surfaces can also be so multifaceted and porous that creating a protective film that covers every hole and deep trench is impossible with most technologies. When tolerances are tight, making sure the protective layer is even and conformal also becomes a challenge.

This is where atomic layer deposition can help. In the following, we will introduce three usage areas of ALD moisture barriers: PCBs, scintillators and OLED displays.

Example 1: Humidity protection of printed circuit boards

As anyone who has left a piece of electronics in a moist place for too long knows, humidity is enemy number one of modern electronics. Many kinds of sealants, dehumidifiers and moisture barrier bags are being used to tackle the issue, but for the best protection one needs to lay a tight protective layer as close to the components as possible.

With atomic layer deposition, it is possible to create a conformal and invisible coating on the components right on the circuit board. The other options for such coatings are typically much thicker and less secure. For state of the art humidity protection of electronics, ALD is the technology of choice.

Example 2: Moisture barriers for scintillators

Scintillator detector plates are devices that are widely used to measure radiation, for example in the flat panels of digital x-ray machines for capturing the image. They, too, are very sensitive to humidity and need to be protected with a coating.

The challenge is that the surface of a high-resolution scintillator detector looks like a dense miniature bed of nails with pins that are five hundred times longer than they are thick. This is the ultimate example of a high aspect ratio surface that is very difficult to protect with a conformal coating. With an ALD moisture barrier, the scintillator’s lifetime can be expanded significantly.

Example 3: Thin film encapsulation of OLED displays

OLED (Organic Light Emitting Diode) displays have become common during recent years, but their sensitivity to humidity limits the lifetime of the screens. This is the market where the moisture barrier requirements are the toughest. With the displays now becoming flexible, protective glasses and other thick surfaces that have earlier been used to keep humidity out are no longer a possible means of protection.

Thin film encapsulation with ALD is one of the very few technologies that can create a protective layer that offers the required level of humidity protection and completely follows the contours of the surface.

Atomic layer deposition is the ultimate moisture barrier

To keep a dry story short, here are the juicy bits to take away:

1. Protection against humidity and moisture is a typical industrial application of atomic layer deposition.

2. With ALD, we can create moisture barriers that are thinner than the alternatives, yet keep humidity and vapors out better.

3. ALD is the best (if not the only) way to create conformal ultra-thin protective coatings on surfaces with high aspect ratios and complex 3D shapes.

4. When the humidity protection requirements are high, the pixel-perfect quality of ALD coatings makes them great for encapsulation of sensitive surfaces (such as OLED displays), especially if the material to be protected is flexible.

The Too long, didn’t read version of this post would probably just be: No matter what you are trying to protect from moisture, ALD will keep you dry.