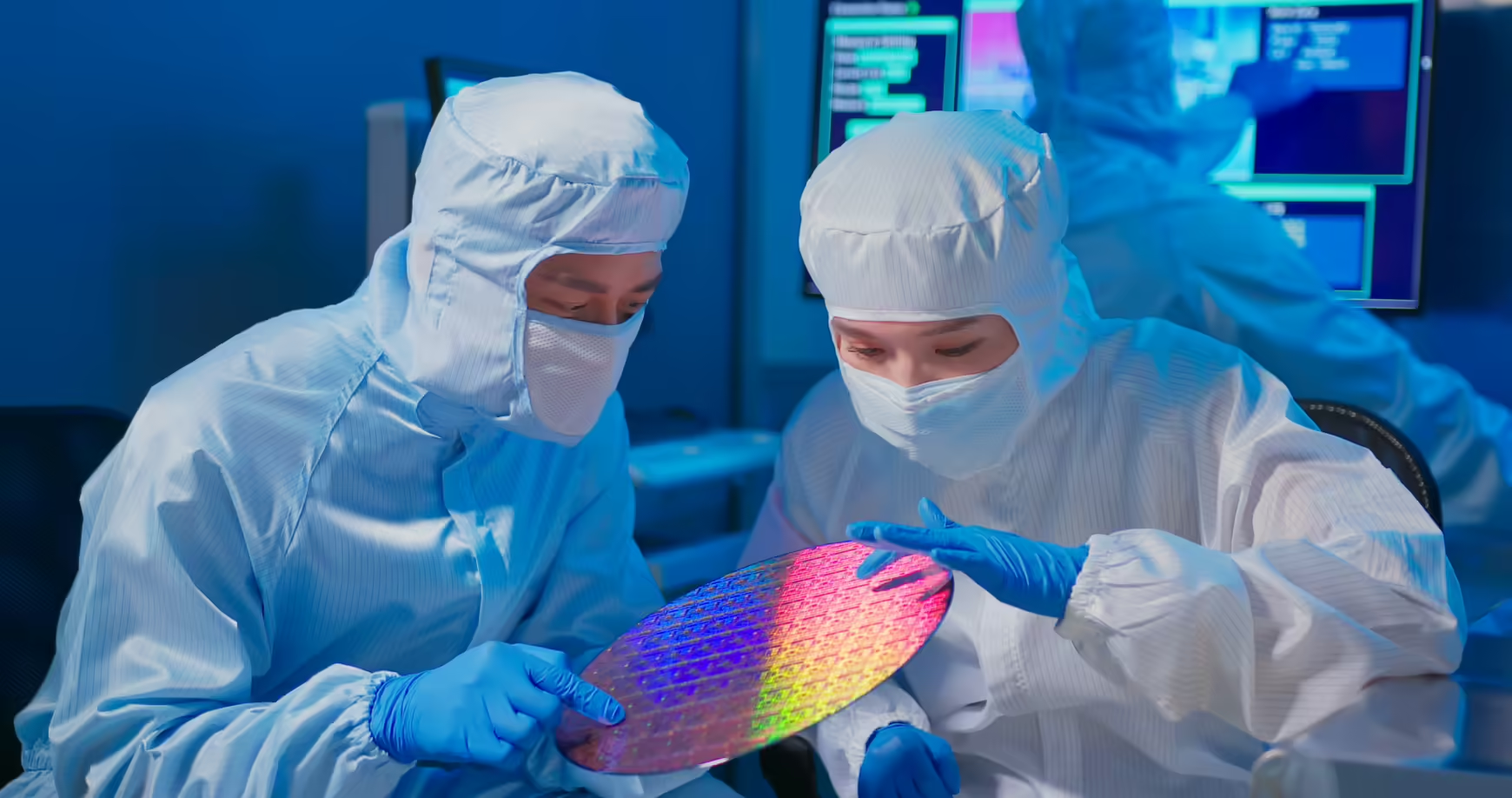

Beneq C2R™- The Era of Spatial ALD is Here

Beneq C2R™ delivers low-temperature, plasma-enhanced spatial ALD with growth rates of up to 2000 nm/h. Optical designers can access unmatched tunable refractive index and zero-stress properties — for AR/VR waveguides, bandpass filters, and more. Unlock dense, uniform films at breakthrough deposition rates with Beneq C2R™ .