Service

Coating services

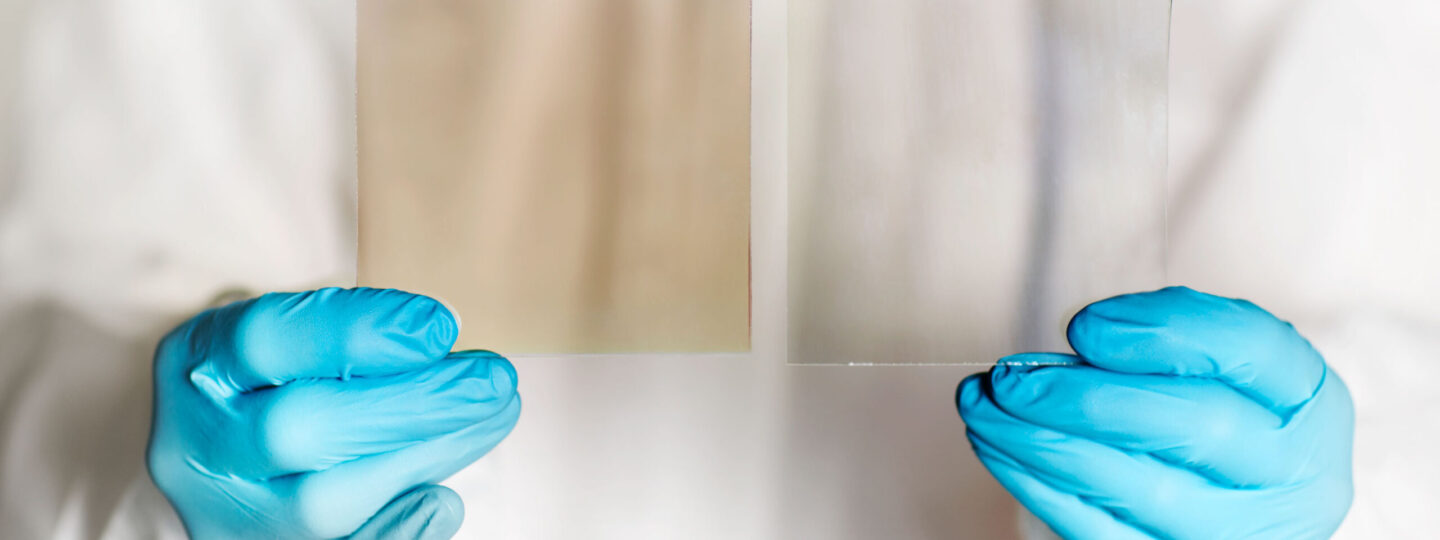

Do you want to get the best available conformal ALD coating for your products without initial capital investments? You can outsource the whole production of your customized ALD films to Beneq.

Outsourced ALD coating – fastest way to market!

The fastest way to market with a new ALD film solution is to outsource the production to Beneq.

From a proof of concept with your specific application requirements to pilots and completely outsourced coating solutions, the world’s largest ALD-dedicated plant is at your service.

Beneq Coating Services is a great way to explore the high-performance ALD technology at a low investment threshold and limited risk.

Easy pilots or completely outsourced production – you choose

You can select Beneq Coating Services for pilot production or completely outsourced ALD coating.

If you want the fastest way to full-blown production, it is possible to outsource the whole production of thin films to Beneq Coating Services. This makes sense if you want to get the best available conformal coating without initial capital investments.

If you choose to buy your own ALD equipment, but want to accelerate the start of the industrial ALD production, we offer the possibility to pilot production at the Beneq ALD factory during equipment deliveries until your own production has been set up. Beneq Coating Services and Support are also happy to assist with any customization, optimization or installation work you may need.